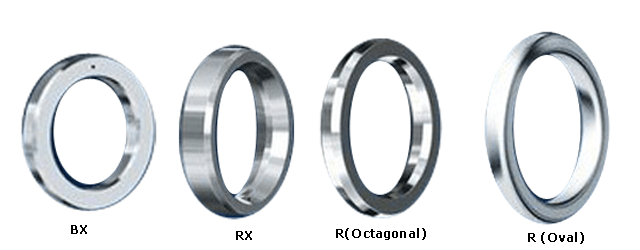

A Ring Joint Gasket (RTJ) provides a strong and durable metal-to-metal seal between two mating RTJ flanges. As the flanges are bolted, the softer material of the ring joint gasket is “squeezed” into the flanges grooves (made of a harder material) and seals the connection very tightly. RTJ gaskets are available in three styles, R (oval, octagonal), RX, and BX.

Ring joint gaskets (RTJ) ensure a long lasting and strong seal for flanges, valves, piping spools and vessels at high pressure and temperatures (which are typical conditions for many petrochemical processes).

RTJ are available in different designs (called “styles”) and dimensions, as illustrated in the picture below (BX, R, and BX).

The material of RTJ gaskets shall match the flanges material but must have a lower hardness: this to ensure that the gasket, and not the flange, get plastically deformed within the groove of the flange as the two mating flanges are bolted together. In case a harder material for the ring type joint is used, the groove of the flange would be damaged as the flanges are tightened (the hardness values for ring joint gaskets are given below).

| RTJ GASKET MATERIAL | RING ID | ASTM GRADE | DIN GRADE | WKSTOFF NUMBER | AISI GRADE | BS GRADE | OTHER SPECS |

| Soft Iron | D | 1.1003 / 1.0335 | Aramco / StW24 | ||||

| LCS | S | 1.1003 / 1.0335 | Aramco / StW24 | ||||

| CS360 LT | CS360LT | A516 Gr70 | |||||

| 4140 | 4140 | UNS G41400 | 42CrMo4 | 1.7225 | 4140 | ||

| F5 | F5 | UNS K42544 | 12CrMo195 | 1.7362 | 5Cr 1/2Mo | ||

| SS304 | S304 | S30400 | X5CrNi 18 9 | 1.4301 | 304 | 304S15 | |

| SS304L | S304L | S30403 | X2CrNi 18 9 | 1.4306 | 304L | 304SS12 | |

| SS309 | S309 | S30900 | X15CrNiSi2012 | 1.4828 | 309 | 309S24 | |

| SS310 | S310 | S31008 | XX15CrNiSi2520 | 1.4841 | 310 | 310S24 | |

| SS316 | S316 | S31600 | X5CrNiMo18 10 | 1.4401 | 316 | 316S16 | |

| SS316L | S316L | S31603 | X2CrNiMo18 10 | 1.4404 | 316L | 316S11/316S12 | |

| SS316L UREA | S316UG | S31603 | X2CrNiMo 18 14 3 | 1.4435 | |||

| SS316Ti | S316Ti | S31635 | X10CrNiMoTi1810 | 1.4571 | 316Ti | 320S31/320S17 | |

| SS321 | S321 | S32100 | X10CrNiTi18 9 | 1.4541 | 321 | 321S12 | |

| SS347 | S347 | S34700 | X10CrNiNb 18 9 | 1.455 | 347 | 347S51 | |

| SS410 | S410 | S41000 | X10Cr13 | 1.4006 | 410 | 410S21 | |

| Monel 400 | Monel400 | N04400 | NiCu30Fe | 2.436 | |||

| Inconel 600 | INC600 | N06600 | NiCr15Fe | 2.4816 | |||

| Inconel 625 | INC625 | N06625 | NiCr22Mo9Nb | 2.4856 | |||

| Inconel 718 | INC718 | N07718 | |||||

| Incoloy 800 | INC800 | N08800 | X5NiCrAlTi31-20 | 1.4958 | |||

| Incoloy 800H | INC800H | N08810 | 1.4958 | ||||

| Incoloy 825 | INC825 | N08825 | NiCr21Mo | 2.4858 | |||

| 904L | 904L | N08904 | X1NiCrMoCu25-20-5 | 1.4539 | |||

| F51 | F51 | S31803 | X2CrNiMoN22-5-3 | 1.4462 | 2205 /Duplex | ||

| F53 | F53 | S32750 | X2CrNiMoN25-7-4 | 1.441 | |||

| F55 | F55 | S32760 | X2CrNiMoCuWN 25 7 4 | 1.4501 | Zeron 100 | ||

| F60 | F60 | S32205 | Duplex | ||||

| Titanium | Ti | R 50400 | 3.7035 | ||||

| 17-4PH | 17-4PH | S17400 | 1.4542 | 630 | |||

| S254 | S254 | S31254 | X1CrNiMoCuN20-18-7 | 1.4547 | F44 / 6Mo | ||

| C276 | C276 | N10276 | NiMo16Cr15W | 2.4819 | Hastelloy | ||

| Alloy 28 | Alloy28 | N08028 | X1 NiCrMoCuN 31 27 4 | 1.4563 | SANICRO 28 |

| Maximum Hardness of RTJ Gaskets | |||

RTJ Gasket Material | Brinell | HRB | ID |

Soft Iron-S | 90 | 56 | D |

Low Carbon Steel | 120 | 68 | S |

4 – 6% Chrome | 130 | 72 | F5 |

SS 304 Stainless Steel | 160 | 83 | S304 |

SS 316 Stainless Steel | 160 | 83 | S316 |

SS 347 Stainless Steel | 160 | 83 | S347 |

SS 410 Stainless Steel | 170 | 96 | S410 |

| RTJ GASKET RING NUMBER | Diameter P | Width A | Height | Oct C | Oct R1 | NPS / CLASS | |

| Oval B | Oct H | ||||||

| R 11 | 34.14 | 6.35 | 11.2 | 9.7 | 4.32 | 1.5 | 1/2 300 / 600 |

| R 12 | 39.7 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1/2 900 / 1500 |

| R 13 | 42.88 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 3/4 300 / 600 1/2 2500 |

| R 14 | 44.45 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 3/4 900 / 1500 |

| R 15 | 47.63 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1 150 |

| R 16 | 50.8 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1 300 / 1500 3/4 2500 |

| R 17 | 57.15 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1¼ 150 |

| R 18 | 60.33 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1¼ 300 / 1500 1 2500 |

| R 19 | 65.1 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1½ 150 |

| R 20 | 68.28 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1½ 300 / 1500 |

| R 21 | 72.24 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 1¼ 2500 |

| R 22 | 82.55 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 2 150 |

| R 23 | 82.55 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 2 300 600 1½ 2500 |

| R 24 | 95.25 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 2 900 / 1500 |

| R 25 | 101.6 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 2½ 150 |

| R 26 | 101.6 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 2½ 300/ 600 2 2500 |

| R 27 | 107.95 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 2½ 900 / 1500 |

| R 28 | 111.13 | 12.7 | 19.1 | 17.5 | 8.66 | 1.5 | 2½ 2500 |

| R 29 | 114.3 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 3 150 |

| R 30 * | 117.48 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 3 300 / 600 |

| R 31 | 123.83 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 3 300 / 900 |

| R 32 | 127 | 12.7 | 19.1 | 17.5 | 8.66 | 1.5 | 3 2500 |

| R 33 | 131.78 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 3½ 150 |

| R 34 | 131.78 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 3½ 300 / 600 |

| R 35 | 136.53 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 3 1500 |

| R 36 | 149.23 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 4 150 |

| R 37 | 149.23 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 4 300 / 900 |

| R 38 | 157.18 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 4 2500 |

| R 39 | 161.93 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 4 1500 |

| R 40 | 171.45 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 5 150 |

| R 41 | 180.98 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 5 300 / 900 |

| R 42 | 190.5 | 19.05 | 25.4 | 23.9 | 12.32 | 1.5 | 5 2500 |

| R 43 | 193.68 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 6 150 |

| R 44 | 193.68 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 5 1500 |

| R 45 | 211.15 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 6 300 / 900 |

| R 46 | 211.15 | 12.7 | 19.1 | 17.5 | 8.66 | 1.5 | 6 1500 |

| R 47 | 228.6 | 19.05 | 25.4 | 23.9 | 12.32 | 1.5 | 6 2500 |

| R 48 | 247.65 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 8 150 |

| R 49 | 269.88 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 8 300 / 900 |

| R 50 | 269.88 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 8 1500 |

| R 51 | 279.4 | 22.23 | 28.7 | 26.9 | 14.81 | 1.5 | 8 2500 |

| R 52 | 304.8 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 10 150 |

| R 53 | 323.85 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 10 300 900 |

| R 54 | 323.85 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 10 1500 |

| R 55 | 342.9 | 28.58 | 36.6 | 35.1 | 19.81 | 2.3 | 10 2500 |

| R 56 | 381 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 12 150 |

| R 57 | 381 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 12 300 900 |

| R 58 | 381 | 22.23 | 28.7 | 26.9 | 14.81 | 1.5 | 12 1500 |

| R 59 | 396.88 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 14 150 |

| R 60 | 406.4 | 31.75 | 39.6 | 38.1 | 22.33 | 2.3 | 12 2500 |

| R 61 | 419.1 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 14 300 600 |

| R 62 | 419.1 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 14 900 |

| R 63 | 419.1 | 25.4 | 33.3 | 31.8 | 17.3 | 2.3 | 14 1500 |

| R 64 | 454.03 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 16 150 |

| R 65 | 469.9 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 16 300 600 |

| R 66 | 469.9 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 16 900 |

| R 67 | 469.9 | 28.58 | 36.6 | 35.1 | 19.81 | 2.3 | 16 1500 |

| R 68 | 517.53 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 18 150 |

| R 69 | 533.4 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 18 300 600 |

| R 70 | 533.4 | 19.05 | 25.4 | 23.9 | 12.32 | 1.5 | 18 900 |

| R 71 | 533.4 | 28.58 | 36.6 | 35.1 | 19.81 | 2.3 | 18 1500 |

| R 72 | 558.8 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 20 150 |

| R 73 | 584.2 | 12.7 | 19.1 | 17.5 | 8.66 | 1.5 | 20 300 600 |

| R 74 | 584.2 | 19.05 | 25.4 | 23.9 | 12.32 | 1.5 | 20 900 |

| R 75 | 584.2 | 31.75 | 39.6 | 38.1 | 22.33 | 2.3 | 20 1500 |

| R 76 | 673.1 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 24 150 |

| R 77 | 692.15 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 24 300 600 |

| R 78 | 692.15 | 25.4 | 33.3 | 31.8 | 17.3 | 2.3 | 24 900 |

| R 79 | 692.15 | 34.93 | 44.5 | 41.4 | 24.82 | 2.3 | 24 1500 |

| RTJ GASKET RING NUMBER | Dia P | Width A | Height | Oct C | Oct R1 | NPS CLASS | |

| Oval B | Oct H | ||||||

| R 93 | 749.3 | 19.05 | … | 23.9 | 12.32 | 1.5 | 26 300 600 |

| R 94 | 800.1 | 19.05 | … | 23.9 | 12.32 | 1.5 | 28 300 600 |

| R 95 | 857.25 | 19.05 | … | 23.9 | 12.32 | 1.5 | 30 300 600 |

| R 96 | 914.4 | 22.23 | … | 26.9 | 14.81 | 1.5 | 32 300 600 |

| R 97 | 965.2 | 22.23 | … | 26.9 | 14.81 | 1.5 | 34 300 600 |

| R 98 | 1022.35 | 22.23 | … | 26.9 | 14.81 | 1.5 | 36 300 600 |

| R 100 | 749.3 | 28.58 | … | 35.1 | 19.81 | 2.3 | 26 900 |

| R 101 | 800.1 | 31.75 | … | 38.1 | 22.33 | 2.3 | 28 900 |

| R 102 | 857.25 | 31.75 | … | 38.1 | 22.33 | 2.3 | 30 900 |

| R 103 | 914.4 | 31.75 | … | 38.1 | 22.33 | 2.3 | 32 900 |

| R 104 | 965.2 | 34.93 | … | 41.4 | 24.82 | 2.3 | 34 900 |

| R 105 | 1022.35 | 34.93 | … | 41.4 | 24.82 | 2.3 | 36 900 |

| RTJ GASKET RING NUMBER | 720-960 | 2900# | 3000# | 5000# | OD | HEIGHT | WIDTH | GASKET Wt. ( kg ) |

| RX20 | 1 ½ | – | 1 ½ | 1 ½ | 76.2 | 19.05 | 8.74 | 0.24 |

| RX23 | 2, 2 1/16 | – | 93.27 | 25.4 | 11.91 | 0.52 | ||

| RX24 | – | – | 2, 2 1/16 | 2, 2 1/16 | 105.97 | 25.4 | 11.91 | 0.6 |

| RX25 | – | – | – | 3 1/8 | 109.55 | 19.05 | 8.74 | 0.5 |

| RX26 | 2 ½ , 2 9/16 | – | – | – | 111.91 | 25.4 | 11.91 | 0.64 |

| RX27 | – | – | 2 ½, 2 9/16 | 2 ½, 2 9/16 | 118.26 | 25.4 | 11.91 | 0.68 |

| RX31 | 3 , 3 1/8 | – | 3, 3 1/8 | 134.54 | 25.4 | 11.91 | 0.78 | |

| RX35 | – | – | – | 3, 3 1/8 | 147.24 | 25.4 | 11.91 | 0.86 |

| RX37 | 4 , 4 1/16 | – | 4, 4 1/16 | – | 159.94 | 25.4 | 11.91 | 0.95 |

| RX39 | – | – | – | 4, 4 1/16 | 172.64 | 25.4 | 11.91 | 1.03 |

| RX41 | 5, 5 1/8 | – | 5, 5 1/8 | – | 191.69 | 25.4 | 11.91 | 1.15 |

| RX44 | – | – | – | 5, 5 1/8 | 204.39 | 25.4 | 11.91 | 1.23 |

| RX45 | 6, 7 1/16 | – | 6, 7 1/16 | – | 221.84 | 25.4 | 11.91 | 1.34 |

| RX46 | – | – | – | 6, 7 1/16 | 222.25 | 28.58 | 13.49 | 1.66 |

| RX47 | – | – | – | 8 | 245.26 | 41.28 | 19.84 | 3.88 |

| RX49 | 8, 9 | – | 8, 9 | 280.59 | 25.4 | 11.91 | 1.72 | |

| RX50 | – | – | – | 8, 9 | 283.36 | 31.75 | 16.66 | 2.43 |

| RX53 | 10, 11 | – | 10, 11 | 334.57 | 25.4 | 11.91 | 2.06 | |

| RX54 | – | – | – | 10, 11 | 337.34 | 31.75 | 16.66 | 2.92 |

| RX57 | 12, 13 5/8 | – | 12, 13 5/8 | 391.72 | 25.4 | 11.91 | 2.42 | |

| RX63 | – | – | 14 | 441.73 | 50.8 | 27 | 11.96 | |

| RX65 | 16, 16 3/4 | – | – | – | 480.62 | 25.4 | 11.91 | 3 |

| RX66 | – | – | 16, 16 3/4 | – | 457.99 | 31.75 | 16.66 | 4.25 |

| RX69 | 18 | – | 544.12 | 25.4 | 11.91 | 3.41 | ||

| RX70 | – | – | 18 | – | 550.06 | 41.28 | 19.84 | 9.12 |

| RX73 | 20, 21 1/4 | – | – | – | 596.11 | 31.75 | 13.49 | 5.27 |

| RX74 | – | – | 20, 20 3/4 | – | 600.86 | 41.28 | 19.84 | 10.01 |

| RX82 | – | 1 | – | – | 67.87 | 25.4 | 11.91 | 0.36 |

| RX84 | – | 1 ½ | – | – | 74.22 | 25.4 | 11.91 | 0.4 |

| RX85 | – | 2 | – | – | 90.09 | 25.4 | 13.49 | 0.4 |

| RX86 | – | 2 ½ | – | – | 103.58 | 28.58 | 15.09 | 0.81 |

| RX87 | – | 3 | – | – | 113.11 | 28.58 | 15.09 | 0.9 |

| RX88 | – | 4 | – | – | 139.29 | 31.75 | 17.48 | 1.46 |

| RX89 | – | 3 ½ | – | – | 129.77 | 31.75 | 18.26 | 3.09 |

| RX90 | – | 5 | – | – | 174.63 | 44.45 | 19.84 | 7.75 |

| RX91 | – | 10 | – | – | 286.94 | 45.24 | 30.18 | 1.5 |

| RX99 | 8 | – | 8 | – | 245.67 | 25.4 | 11.91 | 2.2 |

| RX201 | – | – | – | 1 3/8 | 51.46 | 11.3 | 5.74 | 0.1 |

| RX205 | – | – | – | 1 13/16 | 62.31 | 11.1 | 5.56 | 0.13 |

| RX210 | – | – | – | 2 9/16 | 97.64 | 19.05 | 9.53 | 0.35 |

| RX215 | – | – | – | 4 1/16 | 140.89 | 25.4 | 11.91 | 0.8 |

| RTJ GASKET RING NUMBER | 2000# | 3000# | 5000# | 10000# | 15000# | 20000# | OUTSIDE DIA | HEIGHT OF THE RING | WIDTH OF THE RING | RTJ GASKET WEIGHT KG |

| BX 150 | – | – | – | 1 11/16 | 1 11/16 | – | 72.19 | 9.3 | 9.3 | 0.13 |

| BX 151 | – | – | – | 1 13/16 | 1 13/16 | 1 13/16 | 76.4 | 9.63 | 9.63 | 0.15 |

| BX 152 | – | – | – | 2 1/16 | 2 1/16 | 2 1/16 | 84.68 | 10.24 | 10.24 | 0.19 |

| BX 153 | – | – | – | 2 9/16 | 2 9/16 | 2 9/16 | 100.94 | 11.38 | 11.38 | 0.29 |

| BX 154 | – | – | – | 3 1/16 | 3 1/16 | 3 1/16 | 116.84 | 12.4 | 12.4 | 0.4 |

| BX 155 | – | – | – | 4 1/16 | 4 1/16 | 4 1/16 | 147.96 | 14.22 | 14.22 | 0.55 |

| BX 156 | – | – | – | 7 1/16 | 7 1/16 | 7 1/16 | 237.92 | 18.62 | 18.62 | 1.87 |

| BX 157 | – | – | – | 9 | 9 | 9 | 294.46 | 20.98 | 20.98 | 2.97 |

| BX 158 | – | – | – | 11 | 11 | 11 | 352.04 | 23.14 | 23.14 | 4.35 |

| BX 159 | – | – | – | 13 5/8 | – | – | 426.72 | 25.7 | 25.7 | 6.53 |

| BX 160 | – | – | 13 5/8 | – | – | – | 402.59 | 23.83 | 13.74 | 3.06 |

| BX 161 | – | – | 16 ¾ | – | – | – | 491.41 | 28.07 | 16.21 | 5.35 |

| BX 162 | – | – | 16 3/4 | 16 3/4 | 16 3/4 | – | 475.49 | 14.22 | 14.22 | 1.94 |

| BX 163 | – | – | 18 3/4 | – | – | – | 556.16 | 30.1 | 17.37 | 6.9 |

| BX 164 | – | – | – | 18 3/4 | 18 3/4 | – | 570.56 | 30.1 | 24.59 | 5.86 |

| BX 165 | – | – | 21 ¼ | – | – | – | 624.71 | 32.03 | 18.49 | 8.76 |

| BX 166 | – | – | – | 21 ¼ | – | – | 640.03 | 32.03 | 26.14 | 12.82 |

| BX 167 | 26 3/4 | – | – | – | – | – | 759.36 | 35.86 | 13.11 | 8.53 |

| BX 168 | – | 26 3/4 | – | – | – | – | 765.25 | 35.86 | 16.05 | 10.54 |

| BX 169 | – | – | – | 5 1/8 | – | – | 173.51 | 15.85 | 12.93 | 0.73 |

| BX 170 | – | – | – | 6 5/8 | 6 5/8 | – | 218.03 | 14.22 | 14.22 | 1.03 |

| BX 171 | – | – | – | 8 9/16 | 8 9/16 | – | 267.44 | 14.22 | 14.22 | 1.24 |

| BX 172 | – | – | – | 11 5/32 | 11 5/32 | – | 333.07 | 14.22 | 14.22 | 1.56 |

| BX 303 | 30 | 30 | – | – | – | – | 852.75 | 37.95 | 16.97 | – |

The following tables shows how to select the correct ring joint gasket depending on the flange size (NPS), manufacturing norm (ASME or API) and flange rating:

| NOMINAL PIPE SIZE | PRESSURE CLASSES | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASME B16.5 | API 6B | ASME B16.47 Series A | |||||||||||||

| 150# | 300# – 600# | 900# | 1500# | 2500# | 720# – 960# (1) | 2000# | 3000# | 5000# | 10000# | 150# | 300# – 600# | 900# | |||

| 1/2” | – | R-11 | R-12 | R-12 | R-13 | – | – | – | – | – | – | – | – | ||

| 3/4” | – | R-13 | R-14 | R-14 | R-16 | – | – | – | – | – | – | – | – | ||

| 1” | R-15 | R-16 | R-16 | R-16 | R-18 | R-16 | R-16 | R-16 | R-16 | R-82 | – | – | – | ||

| 1 1/4” | R-17 | R-18 | R-18 | R-18 | R-21 | R-18 | R-18 | R-18 | R-18 | – | – | – | – | ||

| 1 1/2” | R-19 | R-20 | R-20 | R-20 | R-23 | R-20 | R-20 | R-20 | R-20 | R-84 | – | – | – | ||

| 2” | R-22 | R-23 | R-24 | R-24 | R-26 | R-23 | R-23 | R-23 | R-24 | R-85 | – | – | – | ||

| 2 1/2” | R-25 | R-26 | R-27 | R-27 | R-28 | R-26 | R-26 | R-26 | R-27 | R-86 | – | – | – | ||

| 3” | R-29 | R-31 | R-31 | R-35 | R-32 | R-31 | R-31 | R-31 | R-35 | R-87 | – | – | – | ||

| 3 1/2” | R-33 | R-34 | – | – | – | – | – | – | R-37 | R-89 | – | – | – | ||

| 4” | R-36 | R-37 | R-37 | R-39 | R-38 | R-37 | R-37 | R-37 | R-39 | R-88 | – | – | – | ||

| 5” | R-40 | R-41 | R-41 | R-44 | R-42 | R-41 | R-41 | R-41 | R-44 | R-90 | – | – | – | ||

| 6” | R-43 | R-45 | R-45 | R-46 | R-47 | R-45 | R-45 | R-45 | R-46 | – | – | – | – | ||

| 8” | R-48 | R-49 | R-49 | R-50 | R-51 | R-49 | R-49 | R-49 | R-50 | – | – | – | – | ||

| 10” | R-52 | R-53 | R-53 | R-54 | R-55 | R-53 | R-53 | R-53 | R-54 | R-91 | – | – | – | ||

| 12” | R-56 | R-57 | R-57 | R-58 | R-60 | R-57 | R-57 | R-57 | – | – | – | R-57 | R-57 | ||

| 14” | R-59 | R-61 | R-62 | R-63 | – | R-61 | R-61 | R-61 | – | – | – | R-61 | R-62 | ||

| 16” | R-64 | R-65 | R-66 | R-67 | – | R-65 | R-65 | R-65 | – | – | – | R-65 | R-66 | ||

| 18” | R-68 | R-69 | R-70 | R-71 | – | R-69 | R-69 | R-69 | – | – | – | R-69 | R-70 | ||

| 20” | R-72 | R-73 | R-74 | R-75 | – | R-73 | R-73 | R-73 | – | – | – | R-73 | R-74 | ||

| 22” | – | – | – | – | – | – | – | – | – | – | R-80 | R-81 | – | ||

| 24” | R-76 | R-77 | R-78 | R-79 | – | – | – | – | – | – | – | R-77 | R-78 | ||

| 26” | – | – | – | – | – | – | – | – | – | – | – | R-93 | R-100 | ||

| 28” | – | – | – | – | – | – | – | – | – | – | – | R-94 | R-101 | ||

| 30” | – | – | – | – | – | – | – | – | – | – | – | R-95 | R-102 | ||

| 32” | – | – | – | – | – | – | – | – | – | – | – | R-96 | R-103 | ||

| 34” | – | – | – | – | – | – | – | – | – | – | – | R-97 | R-104 | ||

| 36” | – | – | – | – | – | – | – | – | – | – | – | R-98 | R-105 | ||

| NPS | PRESSURE RATING | |||||

|---|---|---|---|---|---|---|

| API 6BX | ||||||

| 2000# | 3000# | 5000# | 10000# | 15000# | 20000# | |

| 1 11/16″ | – | – | – | BX-150 | BX-150 | – |

| 1 13/16″ | – | – | – | BX-151 | BX-151 | BX-151 |

| 2 1/16″ | – | – | – | BX-152 | BX-152 | BX-152 |

| 2 9/16″ | – | – | – | BX-153 | BX-153 | BX-153 |

| 3 1/16″ | – | – | – | BX-154 | BX-154 | BX-154 |

| 4 1/16″ | – | – | – | BX-155 | BX-155 | BX-155 |

| 5 1/8″ | – | – | – | BX-169 | – | – |

| 6 5/8″ | – | – | – | BX-170 | BX-170 | – |

| 7 1/16″ | – | – | – | BX-156 | BX-156 | BX-156 |

| 8 9/16″ | – | – | – | BX-171 | BX-171 | – |

| 9″ | – | – | – | BX-157 | BX-157 | BX-157 |

| 11″ | – | – | – | BX-158 | BX-158 | BX-158 |

| 11 5/32″ | – | – | – | BX-172 | BX-172 | – |

| 13 5/8″ | – | – | BX-160 | BX-159 | BX-159 | BX-159 |

| 16 3/4″ | – | – | BX-161 BX-162 | BX-162 | BX-162 | – |

| 18 3/4″ | – | – | BX-163 | BX-164 | BX-164 | – |

| 21 1/4″ | – | – | BX-165 | BX-166 | – | – |

| 26 3/4″ | BX-167 | BX-168 | – | – | – | – |

| 30″ | BX-303 | BX-303 | – | – | – | – |

Behind Gasket India 'S growth and success there is years of experience working in steel industry & closely monitoring our customer's demands. Exclusive technology, certified products, high quality standards and perfect customer's services: this is Gasket India a true performer in the global market and a reliable partner for its customers.

Ratan Height A Wing, 14th floor, 1402, Gilder Lane, Opp Navjeevan Society, near Mumbai Central, 400008

gasketindia1@gmail.com

info@gasketindia.com

gasketonline1@gmail.com

+91 9930551137

+91 9082065807