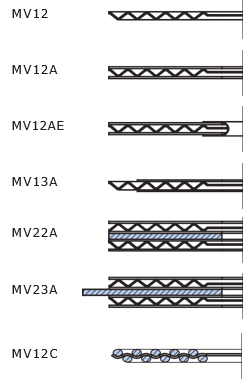

Corrugated gaskets without layer

PROPERTIES AND APPLICATION

There are different types of metal gaskets, like flat, groove, tongue and sectional ones. They are used where compressibility (elasticity) of sealing material is not required. The construction of such gaskets based on the principle of different hardness of adjacent materials. These gaskets come in various shapes and there are almost no limits concerning their size.

There are different types of metal gaskets, like flat, groove, tongue and sectional ones. They are used where compressibility (elasticity) of sealing material is not required. The construction of such gaskets based on the principle of different hardness of adjacent materials. These gaskets come in various shapes and there are almost no limits concerning their size.

The corrugated metal gaskets have been proven to be both reliable and cost- effective for the application on flanges and heads where bolt loading is sufficient. Their operation principle is based on different degrees of hardness of adjacent materials. The sealing effect is produced by the constant load to which a gasket is exposed. They are used in applications, which require mechanical strength, thermal conductivity, as well as temperature and corrosion resistance. They are particularly useful when compressibility is not a factor and where sufficient clamping force is available. Metal gaskets feature greater mechanical strength, better heat transfer and resistance to hi her temperatures and pressures, and can offer advantages over the clad type gaskets in certain applications.

Corugated gaskets with soft layer

Corrugated metal is covered with graphite, ceramic or PTFE layers. An additional finishing layer is applied depending on the requirements of the medium to be sealed. Such gaskets are used on uneven or distorted sealing surfaces, where more elastic materials with better sealing performance are needed.

Corrugated metal is covered with graphite, ceramic or PTFE layers. An additional finishing layer is applied depending on the requirements of the medium to be sealed. Such gaskets are used on uneven or distorted sealing surfaces, where more elastic materials with better sealing performance are needed.

The corrugated metal gaskets with soft layer on both sides are used in low-pressure applications in large diameter flue as ducts at hi h temperatures. The use of corrugated gaskets eliminates the problem of difficult handling with large non- metal gaskets used in those applications. They are suitable for as pipes and valve caps, or wherever acids, oils and chemicals are found. They can be used at lower pressures and hi her temperatures.

ADVANTAGES

- Outstanding mechanical strength and thermal conductivity.

- Capable of withstanding hi h temperatures.

- There are almost no limitations regarding size.

- Solid construction provides stability even for large diameters and ensures trouble-free handling and installation.

SHAPE AND CONSTRUCTION

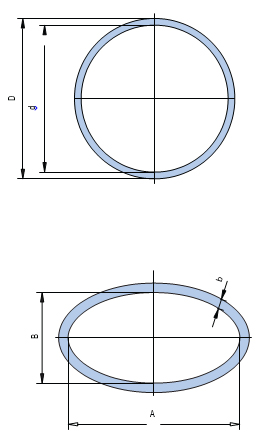

The metal gaskets are produced in several types to meet the most demanding applications. Shapes: Round, Oval, Rectangular, etc.

MATERIALS FOR METAL AND CORUGATED METAL GASKETS |

||

Material |

ASTM |

DIN Material No. |

Low Carbon Steel |

Soft iron (CS) |

1.0333 |

Stainless steel |

AISI 304 |

1.4301 |

Stainless steel |

AISI 316, 316 L |

1.4401, 1.4404 |

Stainless steel |

AISI 321 |

1.4541 |

Stainless steel |

AISI 316 Ti |

1.4571 |

SIZE

SIZE

The gasket constructions with an outside diameter 1000 mm is usually made in one piece, larger dimensions are welded. Welding is also recommen- ded for cost-effectiveness.

PROFILE

The metal is 0.l mm thick and the corrugation pitch is 3 mm, 4 mm, l mm or 6 mm depending on the width and size of the gaskets. The thickness of corrugation is approx. 1mm to 1.l mm, depending on gasket size. Corrugated metal is covered with graphite, ceramic or PTFE layers in thickness 0.l mm - 2 mm.

Behind Gasket India 'S growth and success there is years of experience working in steel industry & closely monitoring our customer's demands. Exclusive technology, certified products, high quality standards and perfect customer's services: this is Gasket India a true performer in the global market and a reliable partner for its customers.

Ratan Height A Wing, 14th floor, 1402, Gilder Lane, Opp Navjeevan Society, near Mumbai Central, 400008

gasketindia1@gmail.com

info@gasketindia.com

gasketonline1@gmail.com

+91 9930551137

+91 9082065807